Drilling Consultancy

Our Services

Introductory consultation

We examine what organisations are doing, and which ones are doing it best, to stay relevant and competitive in this fast-paced industry. We then strategise using the newest and latest technologies in bits, tooling, drilling fluids and equipment to optimise your drilling performance. Our customised recommendations include staff training to enable you to reach your end goal in a timely and cost effective manner. Get in touch today and allow Thomson Tech services to assist you in optimising your drilling performance.

Let us help you achieve your goals. Drill faster, safer, and more profitably.

Tooling and equipment

With years of experience, our staff have the capabilities and expertise to take your business to the next level. At Thomson Tech, we combine our insights and skills to transform your processes and strategies, and in turn, your company. We’re proud to help shape and improve how our client’s select tooling and equipment for their business. Thomson Tech has a unique skill set, not found in any other organisation. The hand picked members of our group have the hands-on experience of the mineral exploration drilling industry and completely understand the requirements of today’s competitive demands. Thomson Tech can assist your entire drilling process. From the basics of down hole tooling selection, right through to a complete custom design of a closed loop drilling fluid reclaim system, Thomson Tech has the answer.

Our expert guidance will optimise your drilling productivity while improving your drilling cost bottom line.

Drilling fluid analysis

Looking to develop and improve your drilling fluid cost but not sure where to turn? Need help planning or executing your next drilling fluid program? Let us help you. Thomson Tech can implement a strategic path to move forward with incremental changes, to build a robust strategy in this rapidly evolving industry, with ever changing technologies and contracts. Our consultants mitigate the risks of taking bold chances and making uninformed and costly decisions.

We create cost efficiencies through prudent analysis of your drilling fluid usage.

Bringing integrity

back to drilling

Know-How

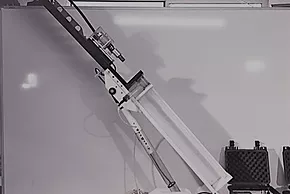

Our hand-built centrifuge has the ability to reach speeds ranging from 10 to 5000 rpm. The clear centrifuge allows you to watch the exact moment a solid would separate away from the drilling fluid via the use of G force.

Hard rock diamond drilling geology is very different to that of Oil and Gas drilling. The majority of the geology drilled in oil and gas has a specific gravity that is under 2.9s.g. In contrast, hard rock drilling will regularly experience formations with huge variances, with specific gravity that can range from 2.2 to 8.9 s.g – three times higher specific gravity and ten times the rotation speeds!

It was clear, I could no longer look to oil and gas for the answer to better hole cleaning. This was one of the many test models made to get a better understanding of how to improve this process.

While making this video and focusing on holding up the very fractured shear zone with a thixotropic drilling fluid. The penny dropped for me that the rod rotational speed was not transferring into the annular space as efficiently as it did when drilling with PHPA’s. While this is stating the obvious, I wouldn’t fully understand the impact of this transferring of energy for another two years. The tight annular space and the specific gravity of geology we drill at high rotational speeds in the mineral exploration industry is extremely different from the oil & gas drilling industry.

Bench Testing 42A was one of the most memorable in many years. The original copy had some good old driller language that required removal and loud music layered over it. It really was one of those moments that you have been hoping to see for the longest time. It was for 42A that Thomson Tech Turbulence was born.

Thomson Tech New Lubricant is something that has never been done before in the mineral exploration drilling industry.

Thomson Tech New Lubricant Is remarkably more efficient at reducing drill rod torque than anything on the market today. The new Thomson Tech lubricant can only be used with the Patented Thomson Tech drill bits and down hole running gear. With one of the many added benefits from it, is the stopping of differential sticking, on the very rare occasion the bore bath passes through a reactive zone. During underground diamond drilling and in cased off bore paths at depth. The new TT-Lubricant is very different to all the oil-based lubricants on the market today and is 100% reclaimable and zero oils.

Refine your drilling practices. Review your drilling fluids program. Improve your cost benefit realisation. Mud schools with unique visual training aids. Our knowledge and experience are at your service.

Drilling Fluid Schools

Develop new fluid management skills with unique visual training tools. This 2hr, on-site training course will upskill your crew and unlock untapped potential.

Fluid Mixing & Reclaiming

Let us guide you through your underground drilling fluid mixing and water recovery needs.

Total Drilling Costs

Review your drilling consumables costs from fluids to drill strings and everything in between. Create cost efficiencies and refine your drilling practices.